9 Simple Techniques For Dust Extractors For Small Workshops

Table of ContentsHow Dust Extractors For Small Workshops can Save You Time, Stress, and Money.What Does Dust Extractors For Small Workshops Mean?More About Dust Extractors For Small WorkshopsExcitement About Dust Extractors For Small Workshops

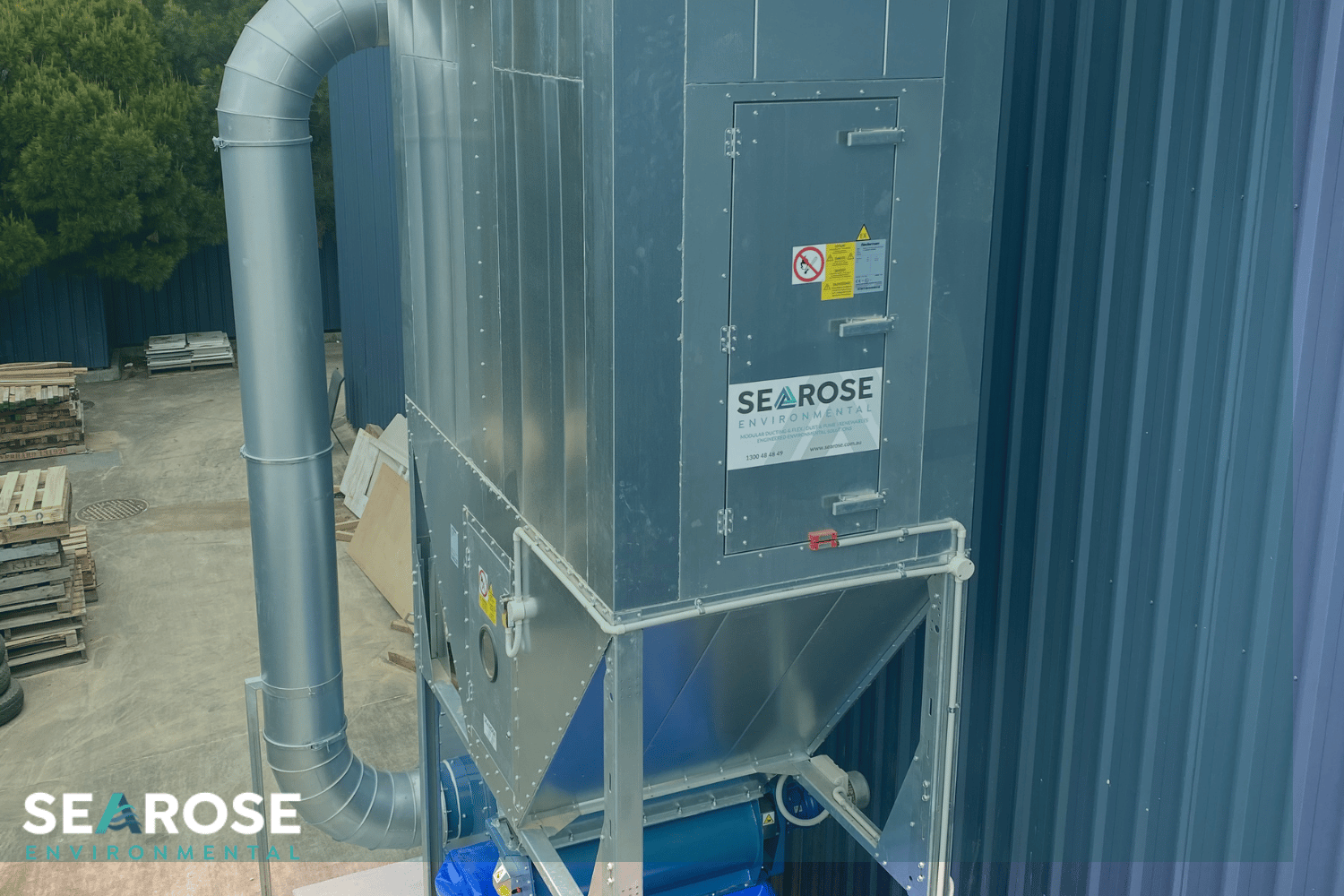

The obstacles for factory dust collection systems focus on crystalline silica dust, carbon monoxide gas, and also heat, which are hazardous combinations. These variables make conference air quality requirements tough and also demanding. When picking a dirt control system for a factory, the initial factor to consider is the capacity of the unit to hold up against rough as well as dangerous work environment problems.

Dirt collection systems for this kind of procedure must be particularly developed to fit the kind of coating being used. The function of the system is to control and also reduce overspray as well as dust.

Though presumably likely to raise air movement as well as movement, this sort of option may mishandle as well as waste energy. The style of the cubicle relies on the pressure of the air going into the cell or cubicle. For the majority of systems, it is very important to have a small vacuum cleaner in the booth to avoid possible favorable stress.

All about Dust Extractors For Small Workshops

An additional approach is just putting the make-up air connection on the top of the booth. No matter the design, it is essential for the cleaning of the air to have cross air flow. Just like a cleanroom, airflow in a thermal spray booth can be either horizontal or downward, though the down layout is best for dirt collection systems.

The pharmaceutical sector is a very regulated industry with extensive as well as exact guidelines. Dust from pharmaceuticals is generated mainly throughout the manufacturing and packaging of items. Each action of generating a medicine, which consists of granulating, drying out, mixing, pressing, finish, as well as grinding, creates huge quantities of dirt that require to be gotten rid of.

Intercepting and also regulating this dissemination is the function of the dust control system. When developing a dust control system for a pharmaceutical plant, the first consideration is mapping the ventilation system to track the path of dust, fumes, existing air movement patterns, and also possible evolutionary modifications. Since numerous pharmaceutical dusts are flammable, the style of the ventilation system is exceptionally critical.

HEPA filters are commonly discovered in pharmaceutical dirt control systems considering that they are the most effective and reliable. Just like a foundry system, they are installed as an additional defense to attain absolutely no emissions. Reusing generates a large amount of dust as a natural outcome of diminishing products to their raw products.

Dust Extractors For Small Workshops Things To Know Before You Buy

Dirt comes company website from after products are shredded, crushed, or have paint or lacquer got rid of. All recycling facilities are called for to comply with air quality standards. As they work to satisfy high quality standards and control pollutants, they have recognized that dirt control is a significant concern, bring about the vast use dirt collection systems to reduce and also consist of the issue. dust extractors for small workshops.

When suppliers choose a dirt control system, they are advised by producers about the kind of system that would best fit their demands given that purchasing and installing a dirt control system is a significant financial investment. Particle issue comes in a wide array of forms, from silicon dust to timber chips as well as sawdust.

The Main Principles Of Dust Extractors For Small Workshops

Textile filter bags in a cartridge system are the most efficient approach for collecting dust. Dirt collection systems are covered to have the dirt and tidy the air.

Plastic Dust High-Density Polyethylene (HDPE) dirt is created in the production of plastic panels when they are shaped and also based on a side trimmer, grinder, or miter saw. Paper Dust Among the extra usual kinds of dirt is paper dust, the side result of the manufacturing of different sorts of paper.

With the intro of dirt collection systems, employees are safer and a lot more safeguarded. Sugar Sugar dirt is the byproduct of the manufacturing visit this page of sweet.

A baghouse system is the recommended system. Rice Dirt Rice dirt has really fine and minute particles that accumulate during the production of rice-based products. A dust collection system is needed for the protection and security of workers. Silica Silica is among the most usual materials in the world. It is a central part of numerous manufacturing procedures, such as the manufacturing of glass, ceramic floor tile, cement, as well as asphalt.